Description

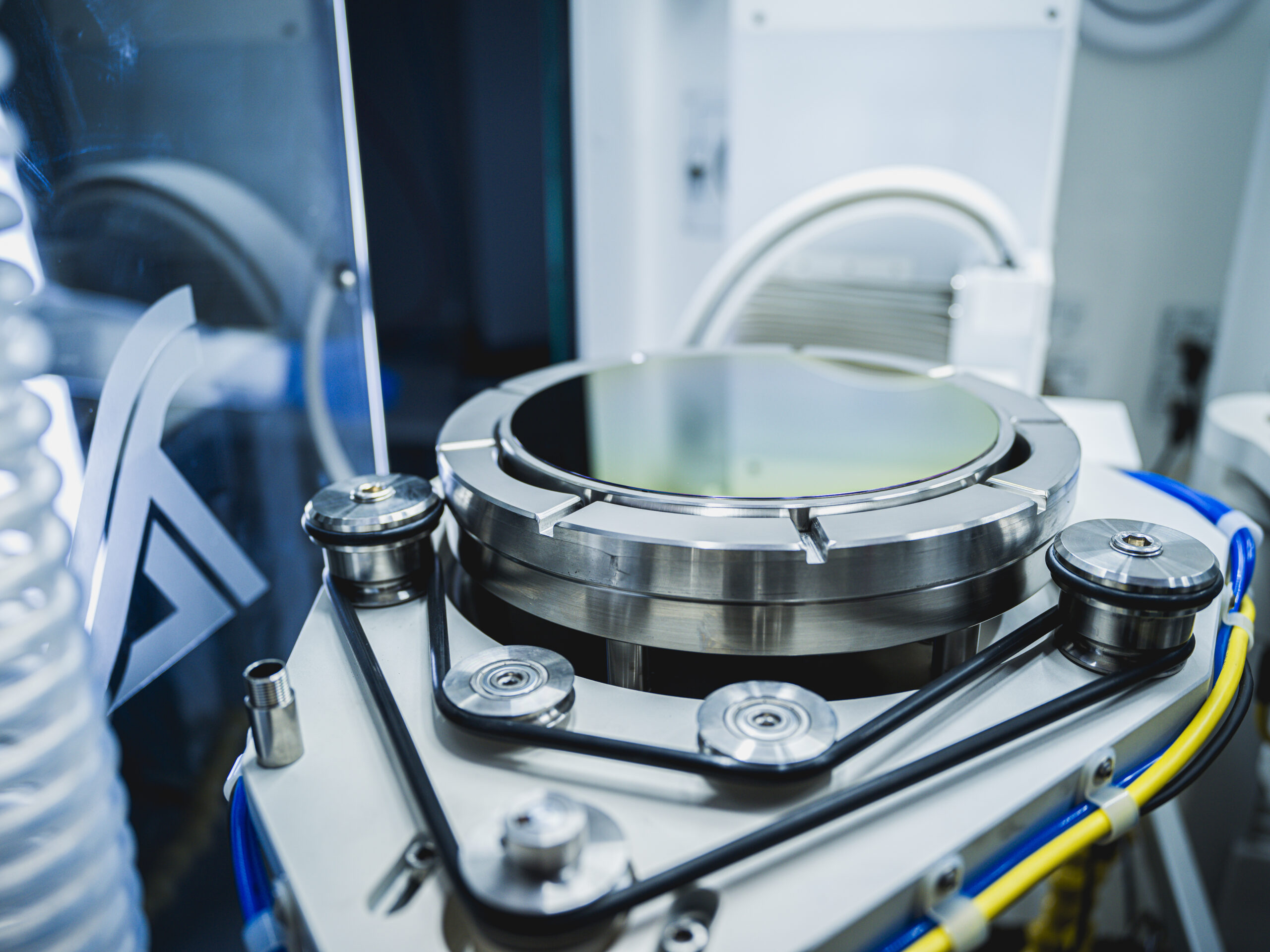

The DL81 and DL82 are high-precision lapping and polishing systems, with the DL82 featuring two automatic workstations and the DL81 combining one automatic and one manual station. They support 700 mm plates and two precision air jigs, handling samples up to 8” (200 mm) jig-held or 12” (300 mm) free lapped. Adjustable air jigs (2–40 kg, 47 kg option) are software-controlled, with in-situ load cells for automatic calibration. Bluetooth-enabled plate flatness control and real-time thickness feedback ensure precision.

An automated jig handling system prevents over-processing, while a service hoist supports safe plate and jig handling. A 15” touch-screen with USB data extraction simplifies operation. Multi-stage processing is enabled by four 3.8 L cylinders, and the metered abrasive feed system (5-100 ml/min) improves efficiency. The sealed enclosure supports hazardous material processing, with an exhaust port for extraction. Real-time monitoring, recipe mode, EtherCAT diagnostics, and a traffic light status tower enhance control and repeatability.

Key Features

-

Flexible Configurations – DL82 (two automatic) or DL81 (one automatic, one manual), supporting 700 mm plates and two air jigs with Bluetooth flatness control and real-time thickness feedback.

-

Advanced Jig Handling – Adjustable air jigs (2–40 kg, 47 kg option) with automated lifting and inversion to prevent over-processing. In-situ load cells ensure precise calibration.

-

Optimized Processing – Multi-stage lapping/polishing with four 3.8 L cylinders and a metered abrasive feed (5-100 ml/min). Sealed system with exhaust port for safe hazardous material handling.

-

Smart Control & Monitoring – 15” touch-screen, USB data extraction, real-time monitoring, and recipe mode for repeatability. EtherCAT diagnostics and traffic light alerts enhance oversight.