Description

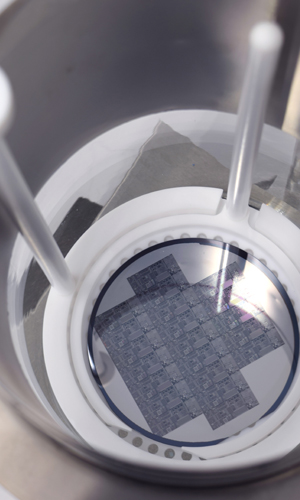

The Logitech Solvent/Vapour Cleaner is the ideal tool for the effective and rapid dissolving and cleaning of temporary wax bonds. Temporary wax bonds tend to be used to temporarily bond samples together or on to a support substrate prior to processing. The unit may be used with samples of up to 4″ in diameter with a wide variety of materials including; Gallium Arsenide (GaAs), Indium Phosphide (InP), Silicon (Si), Ceramics and much more.

It is particularly suited to demounting semiconductor wafers, such as GaAs, InP and Si. In addition, provides an ideal solution to the problems of de-bonding and cleaning stacks of opto-electronic materials such as Lithium Niobate or Lithium Tantalate.

During the operation, the cleaning solution is heated in the bottom section of the cleaner (it is recommended that alcohol such as Iso-propanol (2-Propanol, IPA) for best results), it is then cooled resulting in only clean IPA vapour rising and condensing on the surface of the bonded sample.

During the operation the cleaner emits solvent fumes so therefore must be used in conjunction with a fume extractor unit such as the Logitech Duct Free Fume Cabinet.

Key Features

- Ideal tool for the effective and rapid dissolving and cleaning of temporary wax bonds.

- May be used with samples of up to 4″ in diameter.

- Ideally suited to demounting semiconductor wafers such as GaAs, InP and Si.

- Ideal solution for the problem of de-bonding and cleaning stacks of opto-electronic materials such as Lithium Niobate or Lithium Tantalate.

- Can be used as part of a two-stage demounting process alongside Logitech’s Ecoclear non-solvent cleaning fluid.