Logitech Labs : Large radius optical rod lapping & polishing

31st March 2021

In the Logitech laboratories we are processing materials day in and out, trying to get the best process resolutions for our customers/potential customers.

These can range from tried and tested materials for applications we know in and out, to rare materials with obscure applications we are not too familiar with. Nonetheless, our dedicated team of Process Development Engineers apply their knowledge to the task and devise suitable processes to allow for the achievement of stringent customer specifications.

A new process type we have recently been working on, via proof of concept samples and online training courses, is with the lapping and polishing of optical rods with a large curvature – this was slightly new territory for Logitech as although we have great knowledge and experience in optical rod polishing, historically it tends to be flat ended rods.

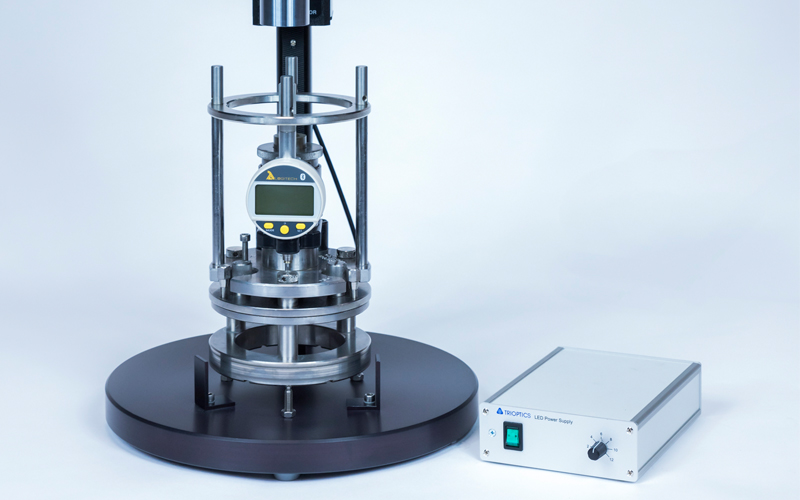

Custom made fixtures were developed in-house for use with one of our precision jigs to hold the sample in place for processing, Logitech offer a range of bespoke fixtures that are custom made to the customers’ requirements on request.

Prior to lapping and polishing the sample was measured using our LG2 Autocollimator for alignment setup. The sample was then mounted on to the PM6 Precision Lapping & Polishing system for lapping. A curved cast iron plate was used in conjunction with a Logitech abrasive for the lapping stage. For the polishing stage, again the PM6 is utilised here but with a Logitech polyurethane polishing pad applied to curved base plate and abrasive replaced with a Logitech polishing fluid.

During and after processing the lapping plate and polishing base plate shape were managed via specially curved test blocks to maintain the correct curvature for the customers’ requirement.

Approved results were achieved utilising the PM6. The curvature of both samples were extremely close to the target required from the customer.

Our team in the labs and the customers were pleased with these results, and we were happy to add a new material shape, and process condition, to our depth of processing knowledge.

Download our brochure on optical processing here or further information on the PM6 precision lapping and polishing system, or any of our systems please get in touch.